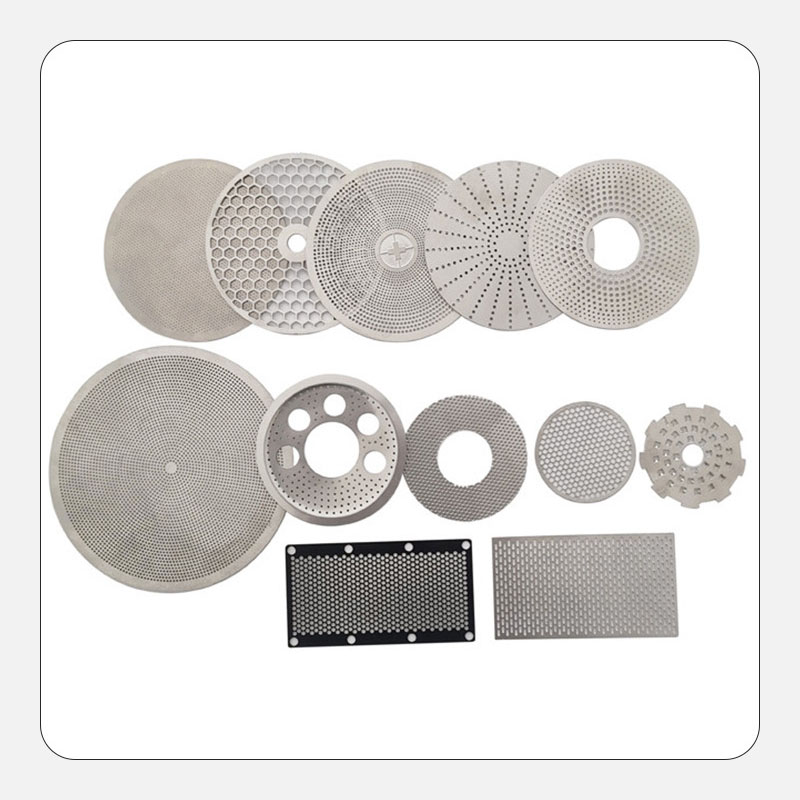

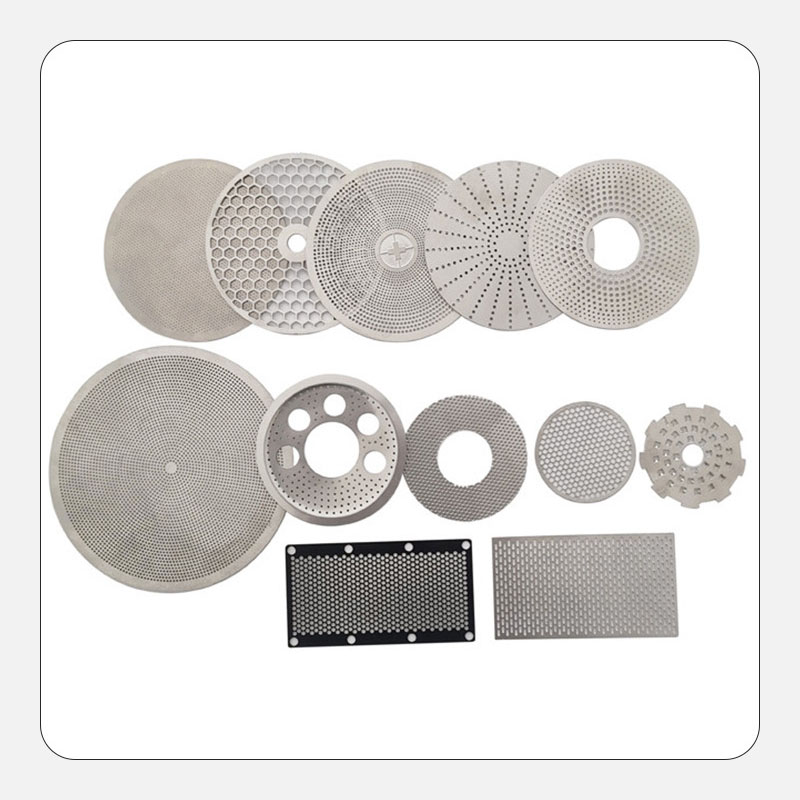

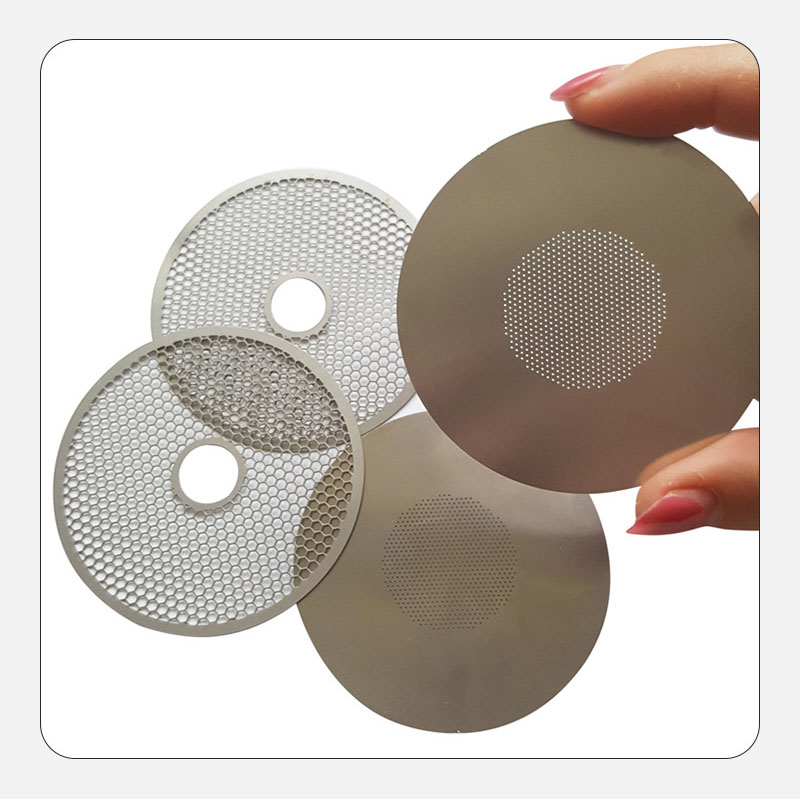

In industrias quasi eget processus, aqua curatio, et cibo vestibulum, traditional fabricata filter Meshes saepe pati a burgat, accentus rimas et repugnat perforationes. Hoc articulum explorat quamChemical Etching TechnologyAchieves diu-term diuturnitatem et ultra-altum praecisione per non-contactus processus, uniformis corrosio potestate, et customized superficiem treatments.

I. Cur Etching outperforms conventional modi

I. limitations de traditional processus

| Collatio |

Laser secans |

Inpulsus |

Chemical Etching |

| In ore finis |

Micro-Slag Residue |

Burr / deformatio metus |

Speculum-lenis marginibus |

| Accentus impulsum |

Calor, affectus zone fragtissime |

Mechanica accentus concentration |

Nulla physica accentus |

| Minimum apertura |

≥0.3mm |

≥0.5mm |

Usque ad 0.05mm |

II. ROSIO resistentia commoda.

. Material integritas: Etching conservat metallum crystallina structuram vs. mechanica damnum a punching / laser.

. Passivation Enhancement: Post-Etch Electrolytic Passivation (Per ASTM A967) Thickens Chromium Oxide Layer per 3-5x.

. Test Data (Tertium Party Report III):

In V% Nacl Salis RAMULUS probat, Etched + Passivated Mass pertuli ≥720 horas rubigo, libera, outperforming Stamped Mesh (CCXL horis).

II. Yanming scriptor IV key technological breakthroughs

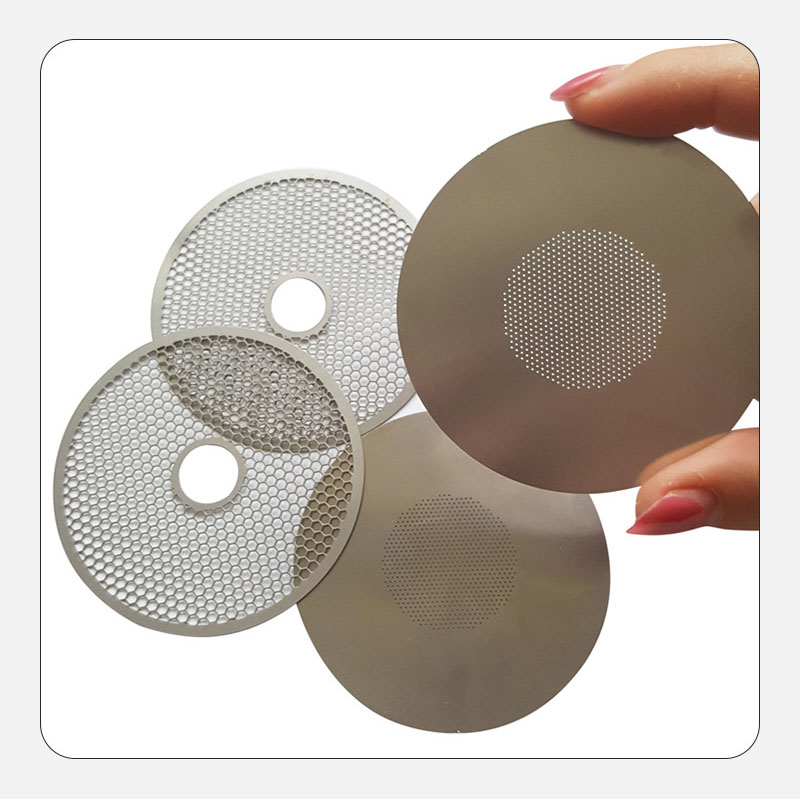

I. Dynamic Compensation Etching ratio. Real-vicis vigilantia etchant concentration / Temperature cum Auto-Moderata RAMULUS pressura ensures ± 0.01mm apertura tolerantia (medicinae-gradus praecisione).

II. Gradient etching potestate. Zonam-specifica persona designs ne "super-Etching ad oras" in uniformis perforationes trans mesh.

III. Hybrid material solutions. Nam acidic environments (E.G .: Electroplating Wastewater), 316L Aliquam Steel + Titanium coating extenditur Lifespan per CC%.

IV. Digital celeri prototyping. Libera eget prototypes in LXXII horis de CAD files (Case: Gallica aqua curatio comitatu scriptor emergency ut timeline).

III. Industria applications

I causa: Marine Fuel FiltersChallenge:

Resistere summus sulphur fuel corrosio cum 0.1mm ± V% apertura constantia.

SOLUTIO Duplici-seesed Etching + electropolishing, DNV GL Certified.

Result: Client est Ordinis volumine crevit XXXV% annuatim in III annis.

Case II: Pharmaceutical Sterile Aeris Filtrationpain Point:

Particulae effusione a signat mesh contaminari pulveres.

Fix: Inconveni Sallet Monobloc Design, Compliant cum FDA XXI Cfr 210,3.

IV. Tua Aliquam optionsyanming Offers:

Material: CCCIV / 316L / Nickel Alloys, etc.

Apertures: 0.05mm-3mm (Custom foramen exemplaria available).

Quisque ISO (IX) I, Rohs, pervenire.

▶ Take actio modo:

[Download] Filter Mesh Design Guidelines

[Get tuum] Free Corrosion Resistance Test Report Home Sampleoptimization Notes:

I, technica visuals: Add an animatum gradiente-Etching tabula ostendens profundum varietas.

II, spera signals: includit a "servivit 20+ regionibus" Interactive tabula.

III, CTAS: Natanting Bullae prope casu studiis ("adversus similes challenges?").

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик